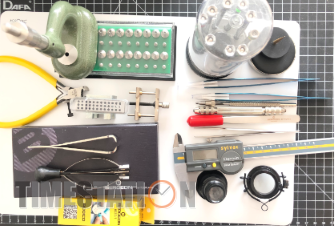

转贴一个英国钟表研究所的用油建议(2008年版),其中有油品介绍,各种尺寸机芯的用油建议,以供拆表爱好者们参考,

不建议死记硬背,要灵活运用手中的相关油品,弄清楚各部位相关油品的互换关系,

然后就海阔天空喽,再不关心所谓的油图喽。。。。。。

为了保证文件的准确性,决定不做任何的翻译和说明,保持原汁原味,若有不明的地方就复制/粘帖翻译咯。

Types of Lubricant – general principles:-

The choice of lubricant to apply to any part of a watch will depend upon its duty.

For example, it is important that the oil applied to the escapement of a watch is of

low viscosity and resistant to oxidation and degradation. Synthetic oils are therefore

generally used; there is much agreement on the particular type to use for different

applications. The use of unsuitable lubricants will harm the action and timekeeping

of the watch.

The viscosity of the oil required for the train of a watch will depend upon the size of

the pivots and the load on the pivot. Manufacturer’s current recommendations are

the best guide in such circumstances; in the absence of such information then a

comparable service guide can be used for guidance. The use of inappropriate oils

may affect the period of operation of a watch, increase wear and reduce the interval

between servicing.

Since there are a number of different types of automatic watches the lubricants used

are usually specific to the type of movement and service manuals are, again, the

ideal source of advice. Use of unsuitable oils will harm the action of the winding

mechanism and affect the going period of the watch.

The choice of oils or greases for winding work is not critical to the operation of the

watch but the lubricant must spread to the various parts of the winding mechanism

but not contaminate other parts of the watch. An unsuitable oil or grease will not

harm the movement but may influence the period between servicing.

For mainsprings a number of options are possible and each manufacturer usually has

their own preferences. Use of inappropriate lubricants may influence the period of

operation of a watch.

Su**ce treatment to prevent spread of oils is commonly used in watches,

particularly escapements. It is less commonly used in clocks but can have similar

advantages. Please refer to “Su**ce Treatment and its Application” (Page 7). Each

manufacturer has their own preferences and some place reliance upon the additives

in the oil and cleanliness to avoid the oil spreading.

There are a number of different types of oil available and, generally, manufacturers

of the various lubricants provide advice on their suitable use. If such instructions

are not available then as a guide the following oils or equivalents can be adopted;

further detail is present in the table to be found in Section 3.3.

Moebius Synt-a-lube 9010 Pivot holes for fast moving wheels, low pressure in

jewelled bearings. e.g. second and escape arbor pivots

and balance.

Moebius 941 Impulse face of pallets and escape arbor pivots for low

frequency calibres: 18000, 19800, 21600 vibs/h

Moebius 9415 grease Impulse faces of pallet and escape arbor pivots for

high frequency (high speed clinergic escapements)

calibres: 28800 vibs/hour

Moebius 9020 Pivot holes for trains, escape wheel and balance pivot

holes in larger calibres

Moebius Synt-HP 1000 Pivot holes for slow moving wheels with high pressure on

jewelled bearings

e.g. Barrel-arbor, centre and third arbors

Moebius KT 22 (Bergeon ref. 2588) or PML (Bergeon ref. 2845)

Mechanical friction systems

e.g. Cannon pinion, winding and setting mechanism,

calendar mechanism and mainspring

Moly OLYT 778 Barrel wall of automatic watches; it is important to

remember to ensure the lubricant is suitable for the

particular material used for the barrel.

Fomblin UT 18 Grease for case gaskets: to ease assembly, assists the

function of moving parts (crown in tubes) and contribute

to the water proofing property of the case.

Ex. Case back, tube, crown, pushers and rotating bezels

Also assists the smooth functioning of the ‘snap’ on

bracelet clasps!

Detailed Guidance for Selecting lubricants:-

The table shows provides a guide for the oils which are appropriate for the size and

frequency of the escapement but, whenever possible, the watchmaker should always

refer to manufacturer’s technical information.

Many believe that oils of the Moebius Microgliss type, D3, D4, and D5 are more prone

to spreading than HP series oils and for this reason D3 and D4 are not listed as generally

recommended. HP 1300 is equivalent to D5. HP500 is equivalent to Moebius 9020.

Notes for the table giving detailed guidance when selecting lubricants:-

+ Chronometers or other pieces with heavy balances will require thicker oil for

balance and escape wheel pivots, such as D5.

++ Automatic calibres may have different metal combinations for the slipping

mainspring end and the barrel and manufacturers instructions must be followed.

* Moebius 8200 series greases include types containing molybdenum and types

suitable for barrels with different materials. For barrels in non–automatic

movements, some watchmakers prefer their own recipes such as a mixture of

molybdenum disulphide paste and heavy mineral oil.

** Pallet pins on pin lever escapements require a lubricant which will remain in

place. Either stabilised grease, (such as Microtime stabilised grease) or 941 and

9415 are suitable depending upon calibre.

|